9 March 2012

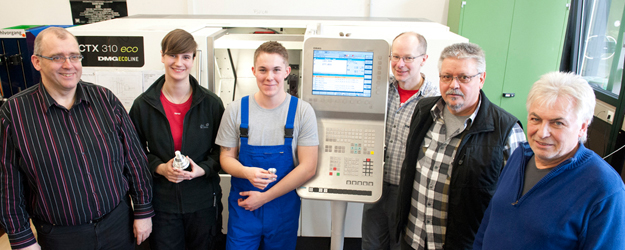

Everybody knows that you go to university for studying. But who knew that Johannes Gutenberg University Mainz (JGU) is also the largest vocational training institution in the region? The workshop at the Institute of Physics has now modernized its training facilities for precision machinists and presented its new CNC machines.

Lukas Krick places a metal cylinder in the state-of-the-art lathe. The CTX 310 DMG Eco Line then starts up. A pane protects against shavings, everyone can watch. A disc-form tool tray gets to work with its various tool inserts. The precision machinists-in-training can control everything with a keyboard. After a few minutes, the piece is done: Krick removes a glistening silver egg cup.

"It's a shot glass," somebody calls out. An atmosphere of celebration pervades the apprentice workshop at the JGU Institute of Physics thanks to the new CNC tools that workshop manager Siegbert Felzer and his co-workers are able to present. The lathe and the milling machine next to it cost about EUR 200,000. "That’s cheap," points out Felzer. Then he explains: "We have the most state-of-the-art workshop on campus; to make sure the vocational training remains sustainable, we need machines like these."

Basis for experiments

The mechanical workshop takes up the entire ground floor of the Institute of Physics. It is the basis for all the experiments that the scientists and students in the upper floors work on. No standardized products are produced here; in fact, each of the objects produced is unique and precisely fashioned for a specific purpose, and they tend to be far more complex than the simple egg cup just made.

"A lot of people don't see the University as a location for vocational training," says Walter Landua. He has been the training manager since 1980. "Back then, it was really bad; we had to print posters ourselves and hang them around town." The situation is not quite so drastic anymore. Twelve apprentice positions are available, and Landua has accompanied 70 trainees. Ninety percent of the precision machinists working at the Institute were trained internally, and many have performed excellently in professional competitions. They have won awards for first in chamber, state, and even the Federal Republic.

Creative trainees sought

"There is a lot of variety to the work we do," says Daniela Hösl, in the third year of her apprenticeship. "We have the chance to contribute our own ideas." The physicists who come to the workshop have a precise plan for their experiments but often have only a vague idea about the tools needed. "If we're lucky, we get at least a drawing," says Felzer. They will then tinker together until the experiment can be carried out. "It is never boring," says Hösl. "We need to think with them. We have to be creative." The apprentices are usually integrated in the three regular teams; thus, they often work on objects that are more than mere exercises.

Landua shows one assignment; several holders for optical lenses and similar tools are arranged on a rail. Tiny wheels make it possible to adjust them in every direction. Nearby are simpler products: decorative elements, steam generators, a model helicopter.

Manual labor is still important

The training manager knows exactly how important the new CNC machines are. However, at the same time, he emphasizes that they can only be used for part of the vocational training. Whoever starts here, will first have a file or a chisel placed in their hand. "Before the trainees can work on the machines, they have to know: How can this material be treated? What angle do they have to set the chisel at?" The first year of the apprenticeship includes a lot of manual labor. "Everybody can cope with the manual work," says Simone Delker, a second-year apprentice, "you just feel it a bit in your arms."

The state-of-the-art tools require entirely different qualities. The CNC machines are controlled using computers; so the apprentices have to be able to write computer code.

"We need extremely independent people," says Felzer. "We may not be as well-known as other training companies, but anybody who comes here is amazed at how well equipped we are here, and at what kind of machines we have." And not just that. "Former apprentices tell us again and again that they would apply right away if a job opened up at our workshop." Felzer knows precisely why: "They can work creatively here. This is very rare these days."